Wire Size and Feeder Spacing for DCC

Summary: Proper wiring results in less problems later. It is one of the most important aspects of Digital Command Control.

| Basic wiring |

|

| Track wiring |

|

Wiring is one part of layout construction which is easier to do correctly the first time than to fix or upgrade it later.

Some of the information presented may seem overly complex or unnecessary. The wiring practices described are based on Best Practices which have been demonstrated to work, both in a home layout and large modular layouts.

No Digital Command Control topic elicits more debate or misunderstandings. Digital Command Control has its own rules for wiring. First mistake many make is the application of Direct Current/Analog practices to DCC. Analog concepts are counterproductive to good performance, this article will attempt to explain the rationale behind DCC Wiring Practices. These recommendations are based on technical reasons and Best Practices.

Wiring

Selecting an Appropriate Wire Gauge

- Power Bus wires must be the correct size (gauge)

- The amount of power available to locomotives will be reduced if inadequately gauged wires are used

- Trains will run slower in areas which are poorly wired

- Consists or multiple trains in the same Power District will run at reduced speeds if the wiring is inadequate

- Wires which are too small may be a fire hazard when used with high current boosters (8 or more amps)

- Poor wiring can result in runaway locomotives. loss of control or damage due to shorts not being detected

Basic Rule: The DCC Signal will seek out the path of least inductance.

Can You Use Wire Which Is Too Heavy?

Experience demonstrates that since you can run more trains with more locomotives using Digital Command Control, you will.

The resulting electrical loads increase for a given layout. In addition, a voltage drop of only two volts is a big issue with Digital Command Control, as compensation is not possible by opening the throttle. Keeping these factors in mind, it is clear a heavier gauge of wire will be required. A small table top layout can reduce these sizes slightly without problems, but larger home or club layouts should adhere to these suggestions - you'll appreciate it in the long run. It's cheaper to do it right the first time than it is to tear it out and do it over!

The DCC Power Bus wiring has impedance, created by the:

- Resistance,

- Inductance, and

- Frequency

Resistance is determined by the conductor's gauge and length[1]. It is linear in nature, as the length of a wire increases so does its resistance. As the diameter (area) decreases, its resistance increases. [2][3]

Wire Gauge and Digital Command Control Signals:

While DC Resistance is low, the AC Impedance is not: An AWG 12 wire may be electrically equivalent to a 20 AWG wire when used with a Digital Command Control signal[4].

Inductance is a property all conductors have, caused by the changing nature of the DCC signal. Its value (in Henries) depends on the diameter and length of the wire. As the diameter decreases, the inductance increases. It also increases with length (which is not linear). The result is a reactive component, XL.

These two properties combine to create Impedance (Z), the AC Resistance. With proper wiring[5], impedance can be managed by controlling the inductance. [6]

The impedance causes energy loss when current flows through the wire, which is lost through heat. The energy loss equals the current squared, times the impedance. This is expressed as I2*R loss (I squared times R). As the wire is a resistor, a voltage drop it will be created.

- Example: If a run of wire has 1 Ohm of resistance, and you pass 1 amp through it, you will see a loss of 1 volt (I*R=1amp*1ohm=1Volt). If you pass 5 amps through it, your loss is 5 volts (5*1=5). You will also convert 25 watts of energy to heat (52*1 = 25*1 = 25 Watt).

- If the resistance is doubled to 2 Ohms, voltage loss increases to 10 volts, and the power loss to 50W (52*2 = 25*2 = 50 Watt).

For the most part, the DC resistance of copper[7] wire is so small that it is expressed as ohms per 100, or 1000 feet. For a short run of a few feet, the resistance is negligible. It becomes an issue with a long run of wire. An equal length of wire is needed to complete the circuit, doubling the impedance of the circuit. High impedance caused by inadequate wiring can prevent proper operation of the booster's over current protection circuit, resulting in damage to track, rolling stock, and even your booster. It can increase ringing, or signal distortion, leading to decoder failures or loss of control issues.

Excessive impedance can result in the motor's PWM signals being imposed on the DCC Power Bus, distorting the DCC signal.

Proper Operation of Overcurrent Protection Devices

An important but often ignored concept is how over current protection works with many DCC boosters. They do not respond to a fixed value, instead reacting to the rate of change in current. A sudden spike triggers it, cutting off current flow before significant damage occurs as opposed to relying on a set value.

The short circuit protection features of your booster are designed to protect the booster, not your expensive locomotive, from damage.

Some boosters can provide an almost unbelievable amount of current for a very brief period of time, upwards of 60A![8]. Significant damage can occur at amperages below the rating of fuses or similar protection devices.

- Poor wiring interferes with the over-current protection circuit's operation. Which could result in damage to your locomotive or its decoder due to excessive current creating heat. Or a short occurs, and something melts because the power was not interrupted. This happens with inadequate wiring slowing the rate of change the booster sees. Or the voltage drop demands more current to maintain the same amount of power. A change from 1A to 1.5A in draw will increase the power dissipation by more than twice.

- Heavy gauge wiring goes a long way to preventing problems. AWG 14 or heavier is not overkill for a power bus, and track feeders of AWG 18 are not that heavy. Choosing wire because it is cheaper or easier to hide is only asking for problems.

- Automotive tail lamps are not recommended for current limiting purposes. This idea belongs in the analog era, not the DCC era.

- Always test your wiring using the quarter test. The booster should cut out immediately. If not, there is a problem.

Harmonics

Different frequencies travel down a wire at different speeds. The result is distortion of the waveform.

This is an important issue. Harmonics are multiples of the fundamental frequency. They cause distortion of the waveform. Harmonics Do Not contribute to the available power. This is mentioned in the NMRA S-9 Electrical Standard years before the NMRA Digital Command Control Standard was written, warning of possible damage to your motor by harmonic currents.

Why is this important with Digital Command Control?

The DCC waveform is a square wave. Square waves are, by their nature, loaded with harmonics. Harmonics waste energy by not contributing to the power available. In extreme cases, half the power available will be wasted in the form of harmonic currents. With poor wiring, these harmonics can alter the shape of the waveform, distorting it to the point the decoder may not be able to read it. If Alternate Power Sources are enabled, the decoder could interpret the DCC waveform as being direct current, and a runaway locomotive occurs.

In DCC one probably will never see that happen, yet energy will still be lost in this manner. That is why the wiring is much heavier than that used for analog operations. Analog power packs will also waste energy when using pulse power modes, the difference being they supply one low current load, whereas a DCC booster and its wiring supply multiple loads demanding a lot more current.

Transmission Line

The idea of the power bus being a transmission line will be put forward in any discussion on DCC Wiring. While technically correct, the application of transmission line theory does not apply, as it was developed to explain phenomena on long telegraph lines. The DCC power bus is measured in meters, not kilometers. The load is dynamic, both in impedance and position, thus altering the length of the transmission line, making it difficult to present a solution to every situation.

Recommended Wire Gauges by Scale

- Note

- Recommended Wire Gauges Shown in an Ampacity Table Are for Copper Wire Only, at 60 Hertz, AC, Sine wave.

- This chart is based on a 5A maximum current on the bus. For an 8A booster, move to the next larger gauge (smaller number).

- These guidelines are based on Technical Requirements and Best Practices.

Wire Size Table, American Wire Gauge

- Main article: Wire Sizes and Spacing/Wire Resistance Table

| Wire Gauge Guidelines for a DCC Power Bus at 5 Amps [9][10][11] | |||||||

|---|---|---|---|---|---|---|---|

| American Wire Gauge (AWG), Copper Wire | |||||||

| https://dccwiki.com/Wire_Sizes_and_Spacing | |||||||

| Scale | Bus Length [12] | Feeder Length [13][14][15] | |||||

| < 21 ft | 21 − 40 ft | > 40 ft | < 5 ft | < 10 ft | |||

| < 6m | 6 − 12m | > 12m | < 1.5M | < 3m | |||

| G | 1:20.3 | 12 | 10 | 8 | 16 | 14 | |

| 1:29 | |||||||

| 0 | 1:48 | ||||||

| S | 1:64 | ||||||

| H0 | 1:87.1 | 14 | 12 − 14 | 18 − 22 | 18 − 20 | ||

| 00 | 1:76.2 | ||||||

| TT | 1:120 | 14 | 20 | ||||

| N | 1:160 | 16 | 14 | 12 | 18 − 22 | 18 − 20 | |

| Z | 1:220 | ||||||

| N−Trak [16] | 16 | 14 | 12 | 18 − 22 | 18 − 20 | ||

| Quick Link to this page: | https://dcc.wiki/o4WZH |

| |||||

Metric Equivalents

| Wire Size Guidelines for DCC Power Bus, 5A Copper | ||||||

|---|---|---|---|---|---|---|

| Metric Equivalents, mm2 | ||||||

| https://dccwiki.com/Wire_Sizes_and_Spacing | ||||||

| Quick Link: https://2tra.in/o4WZH | ||||||

| Scale | Bus Length | Feeder Length | ||||

| < 21 ft | 21 − 40 | > 40 ft | < 5 ft | < 10 ft | ||

| < 6m | 6 − 12m | > 12m | < 1.5M | < 3m | ||

| G | 1:20.3 | 4.0 | 6.0 | 10 | 1.5 | 2.5 |

| 1:29 | ||||||

| 0 | 1:48 | |||||

| S | 1:64 | |||||

| H0 | 1:87.1 | 2.5 | 4.0 - 2.5 | 1.0 - 0.5 | ||

| 00 | 1:76.2 | 1.0 - 0.5 | ||||

| TT | 1:120 | 2.5 | 0.5 | |||

| N | 1:160 | 1.5 | 2.5 | 4.0 | 1.0 -0.5 | 1.0 - 0.5 |

| Z | 1:220 | |||||

| N−Trak | 1.0 - 0.5 | 1.0 - 0.5 | ||||

| N−Trak is based on the N−Trak Wiring RP for DCC http://ntrak.org/ntrak_powerpole_rp.htm | ||||||

| Quick Link: | https://2tra.in/o4WZH |

| ||||

Metric Equivalents to American Wire Gauge

The link below has a table comparing AWG to Metric wire sizes to aid in converting between the two measurements:

- Main article: Wire Sizes and Spacing/Metric to AWG Table

Solid Vs Stranded Wiring

This is another topic which regularly surfaces.

Solid or stranded wire can be used for the power bus and feeders. Stranded wire is flexible and will handle repeated flexing, unlike solid wire which will anneal the copper, making it brittle, which can then break. Stranded wire is also tolerant of nicks caused during stripping. A nick in a solid conductor creates a weak point, where the wire may break.

Feeder Wires

Feeder wires are short lengths of wire that connect the track to the bus. Every few feet, a pair of feeder wires run between the bus and track. The goal: Eliminate voltage drop so the train has full power available to and will not slow down. Also, this ensures that the booster's short circuit protection will work. [17]

Feeder Spacing

For a trouble-free railroad, follow these guidelines for feeder wire spacing. See the table above for guidance on wire gauge.

| Scale | Feeder Spacing |

|---|---|

| G (1:20.3 – 1:29) | Every 12 − 20 feet (4m-6m) |

| I (1:32) | |

| O (1:48) | |

| S (1:64) | |

| HO (1:87.1) 00 (1:76) |

Every 3 to 6 feet. [17] |

| TT (1:120) |

Depending on size of the layout: [17] Mainline ≤ 250 feet: every 4ft, 250 − 450ft of mainline: every 3 ft, > 450 ft: Every piece of track. Short sections (≤ 5") should connect to a bigger section. |

| N (1:160) |

Every piece of track should have its own feeder. Track pieces longer than 18" should have a feeder near each end. [17] |

| Z (1:220) |

Every piece of track should have its own feeder. [17] |

- Main article: Wire Sizes and Spacing/Alternate Feeder Table

Distance Between Feeders

This is directly related to the rail used. With Code 100 to Code 83 (HO Scale) rail, every three to six feet (1 – 2 metres) is recommended. With smaller rail, such as Code 55, more feeders will be needed as the impedance of the rail will have increased. Do not rely on the friction fit of rail joiners to conduct current.

Length of Feeders

Feeders should be as short as practically possible. There will be exceptions, but as a rule, no longer than needed. Options include routing the power bus for easier and shorter feeder installation, such as routing it diagonally across a yard. Or branching off from the power bus to feed a number of sidings.

Don't Place Feeders at the End of a Short Section

If you have a very short block or track section, and will only have one set of feeders, place it in the middle instead of at either end. Don't worry if you can't get it exactly in the middle. There is the ideal and then there is the practical: aim for the ideal, but keep the practical in sight.

Connection Methods

Feeders can be installed in a variety of ways. They will be soldered to the track, and connected to the power bus by soldering or mechanical means, such as Marrettes, splices, crimped on terminals, or insulation displacement connectors (IDC).

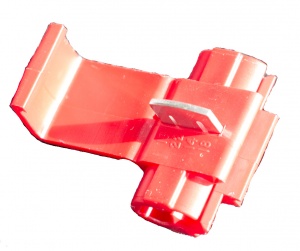

When choosing a mechanical method of joining the feeder to the track bus, make sure it can handle the differences in wire gauge. IDCs are made for joining two wires, and they are available for different gauges, as well as various combinations of wire gauges.

IDCs are also known as ScotchLoks (manufactured/invented by 3M), sometimes called suitcase connectors. The 3M devices are superior in design and construction to generic knock-offs.

- 3M makes a T-Tap, an IDC you crimp onto the wire, which has a tab which will accept an appropriately sized crimp-on female connector. These can be useful to make connections for feeders as well, with the advantage of being able to be disconnected.

Power (Track) Bus Wiring

- The Power Bus [18] carries power from the booster to the track using heavy gauge wires

- Feeders (sometimes called droppers) connect the rails to the track bus, using lighter gauge wires

Below is some information to get the most of your system by using the correct wire types, gauge, and installation methods.

Wiring a Power Bus

The Power Bus connects the booster to multiple points along the track. The bus follows the track from below, and feeders are regular intervals connect the track to the power bus. This minimizes any voltage losses caused by the impedance of the rails. As demonstrated by the table below, Code 100 rail is equivalent to a 24AWG wire. By paralleling the track with a heavy gauge power bus, the effect of this higher resistance can be negated.

- A 24-gauge wire has 9 times the resistance of a 14-gauge wire. The difference between 24 and 12 gauge is almost 15 times. [19]

For the greatest benefit of the power bus, the wires should be kept close together to minimize their impedance. This may be referred to as Closing the Loop, as it keeps the magnetic field around the wires as tight as possible, reducing their inductive properties.

The location of a booster should allow the power bus to fed from the center, with an equal length of bus on either side of the booster, to minimize the total bus length. Instead of a 50-foot run, splitting it into two runs of 25 feet is better from an electrical standpoint.

If the track plan forms a loop, there should be a double gap at the point farthest from the booster. The power bus should not form an electrical loop either.

Power Bus Alignment

In many cases the power bus will follow the main line. For other applications, some variations may be required.

Multiple Track Mainlines

One power bus can supply a double or multiple track mainline, as well as adjacent sidings. There will be more feeders to install.

Sidings and Branch Lines

Sidings and branch lines which are not parallel to the main line and its power bus can be supplied by their own bus, or by using a sub bus tapped off from the power bus.

Yard Tracks

One way to easily wire a yard with multiple tracks is to zig-zag the power bus beneath the yard, forming a V or W shape, to minimize the length of the feeders.

Engine Facilities

Some modellers desire the ability to control the application of power to their locomotive storage and ready tracks. This is possible using a SPST or DPST toggle switch. What is important is to avoid attempting to save on wire by only running a one wire loop to the switch and back. This will introduce impedance into the circuit which can cause problems. To minimize the impedance, create a sub-bus off the power bus with a pair of heavy gauge wires, which has the switch inserted in one or both wires, then run that bus to the storage or ready tracks. Much like the power bus, this keeps the impedance low. Running a single wire from a remote location to the fascia and back to the location introduces unnecessary inductance into the loop.

If the ability to control power to these tracks is not an issue, the techniques used to wire branch lines, sidings and yards would apply.

Twisting the Bus Wires

- Main article: Twisting Power Bus Wires

There have been ongoing debates raging about the necessity of twisting the bus wires together since the introduction of DCC. One group says yes, the other believes it is not necessary. Twisting your bus wires together serves two purposes:

- It looks neater

- Reduces the impedance by minimizing the inductive properties of the wires

The same can be achieved by tying the wires together with cable ties. This method actually makes it easier to separate the wires to add feeders.

- If you are planning to add detection, do not twist the wires for a foot or two after the current transformer. This reduces parasitic currents due to capacitance between the wires. For maximum sensitivity keep both wires close to the CT to concentrate the flux.

Impedance

In DCC, the impedance of the wire is important. The Reactive Component (XL) can be much larger than the resistive properties of the wire, controlling Inductive Reactance is important for the electrical performance of your wiring.

Inductance and Impedance Reduction

- Parent article: Inductance

- Also see TN-9 Wiring for DCC & DC Section 2.2 Signal Distortion.

- Managing the impedance (Z) of your track bus is important. While this is an advanced topic, it is important to understand the basic principles to avoid creating problems when wiring.

Three Steps to Managing Inductance:

- Heavy gauge wire

- Avoid long runs

- Keep the pair close together.

It is important to understand that the reactive components of your wiring's impedance have an effect on phase relationships. Since a DCC signal is a pulse made from a fundamental frequency and its multiples (harmonics), as those relationships are altered by the reactive properties of the wiring distortion of the DCC signal results. This results in some frequencies travelling faster than others, distorting the pulse shape.

Capacitance

Twisting the bus wires creates a capacitor, with a value of 1 to 2 pF per inch. Doesn't sound like much, but that can be as much as 480pF over 20 feet. An excessive number of twists in the bus should be avoided. [20]

Capacitance creates a leakage path for the DCC signal, causing issues with current sensing block detection systems. If a block detection system is planned, keep this in mind while the track bus is being installed. Wires feeding a detection block should not be twisted together for at least a foot or more after the current sensor.

Capacitance is determined by the wire: larger gauge (lower numbered) wires have more surface area, plus the thickness of the insulation which forms the dielectric (insulating) portion of a capacitor. The resulting capacitance is created by the area of the plates (the wire's surface) and the distance (thickness of the dielectric) between them.

Power/Track Bus Impedance

Impedance Measurements on a loop made of two 12AWG wires, ~36 feet each for a total loop of ~72'. Average impedance of each wire is 0.8Ω, L = 12.6μH, resistance 0.09Ω. Measurements made at 10kHz.

| Bus Wires | Z (Impedance, Ohms) | Inductance (μH) at 10kHz |

|---|---|---|

| https://dccwiki.com/Wire_Sizes_and_Spacing | ||

| Parallel, >1 foot spacing | 1.38 | 22 |

| Parallel, Tight | 0.57 | 9 |

| Loose Twist | 0.50 | 8 |

As this table demonstrates, the Inductive Reactance (XL) is the dominant factor in the resultant impedance. By managing the inductance, the voltage drop can be kept to a minimum.

- 12AWG has a DC resistance of 1.6Ω per 1000 feet. This loop would be 72/1000 × 1.6 = 0.12Ω. The measured impedance was 1.38Ω, which, at 5A, would result in a voltage drop of 600mV. By reducing the impedance to 0.6Ω, VDrop becomes 300mV. This does not include the burden imposed by the multifunction decoder(s) and the track.

- A calculated approximate value for a 72-foot straight 12AWG wire is: 30µH/foot (1.9Ω) plus 120mΩ, for a total impedance of 2Ω.

Rail Resistance, Nickel Silver

The following table gives the impedance of various codes of rail.

The impedance was found with 1A (at 60Hz) current flowing through the sample, using a current comparator and a detector set at 50μV. The impedance of the rail was calculated by determining the Zero Ohm balance (all impedances were nulled) of the measuring circuit at a 1:1 ratio, then introducing the rail sample to the error winding of the comparator. The impedance is the difference between the balance obtained with and without the sample. By injecting a negative impedance, the impedance of the rail is found when the measuring system is brought back into balance, with the detector indicating that no error current was present in the detection winding. Current comparators are capable of measuring both the ratio and phase displacement very accurately.[21][22][23][24]

| Code of Rail | Impedance per metre, mΩ | Equivalent Wire Gauge | Strands/Gauge |

|---|---|---|---|

| https://dccwiki.com/Rail_Size | |||

| 100 | 76 | 24 | 7/32 |

| 83 | 108 | 26 | 19/38 |

| 70 | 206 | 28 | 19/40 |

- The wire used for an equivalent is stranded. Since the measurements were made at 60Hz, impedance better reflects the results.

- Rail resistance measurement uncertainty is >25ppm (0.0025%). Actual resistance will vary by manufacturer due to alloy and profile.[25]

Some multifunction decoders have increased sensitivity to waveform distortion because:

- The manufacturer has designed them to reject out-of-specification waveforms.

- The default setting is to continue as it was in the absence of a valid waveform (many decoders simply shut down after a packet timeout period). This can make some brands of decoders less sensitive to dirty track resets, at the increased risk of loss of control when waveforms are badly distorted.

- Failure to remove the EU-mandated interference suppression inductors from the loco motherboard is another cause of loss-of-control at speed.

To isolate this issue:

- Remove the vehicle from the track,

- Place in a cradle or on a short section of isolated flex-track (restrain the vehicle if needed),

- Power supplied with jumpers directly from the command station's track output.

- Disconnect the command station from the layout's power bus first!

This process will isolate whether the problem is layout or vehicle wiring.

Other Opinions

- "The track power bus wires should generally be parallel to each other. Slightly twisting the track power bus wires together will virtually eliminate radio interference, but this is not absolutely necessary. Avoid non-parallel wiring which might be tempting when running wires through and around various obstacles. This prevents unnecessary electronic emanations. The trains will not care, but reception of distant AM radio stations might experience some interference if track power bus wires are neither twisted nor parallel." [26]

Digitrax doesn’t require it, and suggests that proper selection of wire gauge and feeder lengths kept to a minimum are essential to reducing resistance and power loss.

Terminating Bus Wires

This is another DCC topic that gets a lot of ink (or maybe electrons moving) on a regular basis.

In general, bus wires should not need termination. However, you may find it beneficial on pre-installed long wire runs and/or in situations in which your experiencing control problems, such as decoders losing their programming or worse, a decoder failure. Refer to your system manual to see what is recommended. The RC Network can absorb some of a voltage spike by giving it an alternate path, instead of your decoder’s front end.

For more information on Bus Snubbers or Terminators, see Bus Termination. Also see the section on Inductance above.

Some manufacturers recommend the installation of a bus terminator, others do not. Digitrax doesn’t recommend them, while some command stations may have the equivalent built in. If the output of the booster is a high impedance, this usually minimizes the issue. A low impedance output driving the track bus with moving higher impedance loads on it will create conditions where ringing[27] is quite possible.

As a rule, they should only be installed if needed, and after proper investigation such as measuring the waveform with an oscilloscope. Share this page

See Also

- Wiring - Primary wiring article.

Calculators

- Electronics and Electrical Engineering Tools

- Wire Self Inductance Calculator

- Parallel Wire Inductance

External Sites

- ↑ Copper is considered to be 100% conductive, other metals and alloys will be less. The DCCWiki references copper unless stated otherwise.

- ↑ Skin Effect is negligible at the DCC signal frequency.

- ↑ Wire_Sizes_and_Spacing/Wire_Resistance_Table: Each step in gauge number represents approximately a 25% change in the diameter of the wire. Three steps will double (or half) the wire diameter.

- ↑ Electrical codes are written with 60 (or 50) Hz Alternating Current in mind.

- ↑ Proper selection of gauge and wiring techniques to manage the inductance.

- ↑ Impedance is the Square Root of the sum of the Squares. Example: R + X = Z, or 3 + 4 = 5. ((32 + 42) = 52). Graphically, this forms a triangle, where the hypotenuse equals the Impedance.

- ↑ Copper is considered to be 100%, modern copper refining can result in better than 100% conductivity.

- ↑ Circuit Breakers which rely on a pre-determined value can allow excessive current to flow before disconnecting.

- ↑ Recommended wire gauge is for a 5-amp current draw, using copper wire.

- ↑ For 10A, decrease by three gauge numbers.

- ↑ It is permissible to use a short length of lighter guage wire to connect to the booster, if necessary.

- ↑ Big Book of DCC by Digitrax: Runs up to 100 feet are possible with 12AWG wire, and 50 feet with 14AWG. This is for one leg; in theory it is possible to have a 100-foot run (14AWG) with the booster in the middle (50 feet on each side). Don't skimp on wiring, plan for future power needs.

- ↑ Feeders should be kept as short as possible.

- ↑ Feeder Length is the recommended maximum length between the track and the DCC Power Bus. Try to keep feeders as short as possible.

- ↑ Do not rely on feeders soldered to a rail joiner. Solder directly to the rail for the most reliable connections.

- ↑ N−Trak is based on the N−Trak Wiring RP for DCC http://ntrak.org/ntrak_powerpole_rp.htm

- ↑ 17.0 17.1 17.2 17.3 17.4 Never rely on rail joiners for reliable electrical connections.

- ↑ This may also be called the Track Bus

- ↑ Rule: The diameter of a wire is doubled or halved every three steps in gauge.

- ↑ A tight twist increases the area while decreasing the distance between the conductors.

- ↑ Values measured with a current comparator and phantom burden at one ampere, 60 Hertz. The impedance of any additional wires was reduced to zero ohms using the phantom burden.

- ↑ https://patents.google.com/patent/US3701008

- ↑ https://books.google.ca/books?id=IyTVaL60VdQC&pg=PA88&lpg=PA88&dq=phantom+burden&source=bl&ots=wjlHm-zVsx&sig=ACfU3U1Zj6pdHoib-uB5Vh56s61ns7r2uQ&hl=en&sa=X&ved=2ahUKEwjmkfePgZb9AhW5mIkEHctrAMcQ6AF6BAg5EAM#v=onepage&q=phantom%20burden&f=false

- ↑ https://ieeexplore.ieee.org/document/4075345

- ↑ At 25ppm the resistance of Code 83 rail per metre will be 108mΩ ± 3µΩ (107.997 – 108.003mΩ). A typical ohmmeter would have resolution 100µΩ, with an error of 11mΩ, 100Ω range (Fluke 8845A 6.5 digit desktop DMM).

- ↑ DIGITAL COMMAND CONTROL; Stan Ames, Rutger Friberg, and Ed Loizeaux, Alt om Hobby AB, 1998, page 38, paragraph 4.1.1

- ↑ Ringing is unwanted oscillations of voltage or current in a circuit. During the signal transition from low to high or high to low, the voltage doesn't immediately stabilize at the desired level; instead, it oscillates briefly before settling down This distorts the signal, which may lead to loss of control. These oscillations may result in voltage spikes of an amplitude great enough to damage a multifunction decoder.