Decoder

Summary: Decoders are used to control various elements on the layout, such as vehicles or turnouts. Multifunction Decoders are used in vehicles, Function Decoders provide functions in a vehicle such as lighting, and Accessory Decoders control turnouts, signals and other accessories.

| Main Topics |

|

| Misc Items |

|

Decoders can be grouped into three categories: Multifunction, Function and Accessory, each having additional sub-classifications. In summary, they are:

- MultiFunction - Used in rolling to stock, such as locomotives to control movement, lights, and sound. Can also be used in cars to control lights or other animations.

- Sound - Responsible for playing noises typically heard around a train, such as a engine sound, horns, and bells. Sound decoders are technically considered a multifunction decoder because many also control the motor and lights.

- Some sound decoders are purely for sound. They can be used to provide sound effects such as mechanical refrigeration or animals in a vehicle.

- Function decoders supply additional functions in a vehicle, or can be used independently to control lighting in vehicles such as a caboose.

- Accessory - Control signals, turnouts, and animations around a layout.

MultiFunction Decoder

- Main article: Multifunction Decoder

Commonly called a mobile decoder, the NMRA refers to these as a multifunction decoder. Multifunction decoders are installed into vehicles such as locomotives or other rolling stock that moves along the rails. It allows complete control of motors, lights, sound, and other functions. Installation may occur at the factory during manufacturing, installed by a third party, such as a hobby shop, or install them yourself.

Multifunction decoders can be further broken down into two types: Retail and OEM. Retail decoders are full function decoders that you buy at the hobby shop for installation, either by the shop or yourself. OEM decoders are supplied directly to the factory for installation in a vehicle during manufacture, and may not have all the functions of a retail decoder. OEM decoders can have custom programming for various functions specific to that model, as well as the appropriate sounds.

Sound Decoder

Another form of multifunction decoder, which in addition to motor and function control, has sound capabilities. The sounds are tied to the motor operation, allowing for realistic effects such as the prime mover loading up, or the beat of a steam locomotive's exhaust. Other effects include dynamic brakes, rod clank, steam cocks opening, and in the case of internal combustion, starting or shut down of the prime mover. Plus, other associated sounds such as horn/whistle, bell, coupler noises and other ambient effects.

While many multifunction decoders are supplied from the factory with a particular sound set, some premium multifunction decoders allow for complete reprogramming with custom sound effects. While you can download new sound files (formatted for that decoder) and load them into a retail decoder, OEM sound files often are locked to a specified decoder model and cannot be loaded into a retail decoder. The ESU LokSound decoders are an example of a multifunction sound decoder which can have custom sound projects loaded onto it. The retail versions are blank when purchased, and can be loaded with a sound project by the dealer, yourself, or someone installing the decoder.

Function Decoder

The Function Decoder provides lighting effects in passenger cars and cabooses. Marker lights can also be included. The decoder will allow some customization and the ability to turn effects on and off. Sometimes they were used in conjunction with a multifunction decoder to provide extra function outputs in addition to the limited number available from the early multifunction decoders. The Decoder Lock feature was developed to aid in programming additional function or sound only decoders with the same address.

Sound Only Decoder

Some sound decoders are designed for use in rolling stock which lacks a motor. These decoders only provide ambient sounds related to that car, such as cattle in a stock car, or the engine noise of the mechanical refrigerator system in a reefer car.

There also were sound decoders designed to be installed in a locomotive in addition to the multifunction decoder which lacked sound. With the introduction of multifunction decoders with integrated sound these types faded away.

Accessory Decoders

- Main article: Accessory Decoder

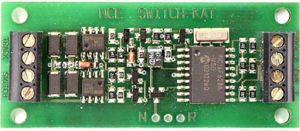

Accessory decoders are normally mounted under the benchwork in a stationary position. Accessory decoders are used to control railway turnouts, structure lights, scene lighting, animation, and signalling. Many have multiple outputs, allowing devices nearby to be controlled from one accessory decoder.

Avoiding Runaway Locomotives

Good trackwork, proper wiring following the recommended best practices, proper power management and eliminating the cause of shorts goes a long way to prevent runaways from occurring. A common cause of runaways is a distorted DCC signal causing the vehicle's multifunction decoder to switch to analog operation, accelerating to full speed in the process.

A runaway is scary, and the only way to stop it is a total shutdown of track power.

Also read the section on Compatibility Issues for technical details on multifunction decoder addressing to avoid a runaway.

Multifunction Decoder Troubleshooting

- Main article: Multifunction_Decoder Troubleshooting

Some multifunction decoders may not properly consist with other decoders, have memory corruption, weak or bad solder joints, track over-voltage, overheating, etc. Troubleshooting can take a bit of time to diagnose and correct. Be sure to read the Multifunction Decoder Troubleshooting article for tips.

Decoder FAQ

Q: What is a decoder?

- Main article: Decoder

A decoder is a device which listens for Digital Packets addressed to it, and then performs whatever action is requested.

There are three types:

Some multifunction decoders are very simple devices providing only motor control and a small selection of lighting options, while others are very complex with multiple special effects, tunable motor response, and sound effects available.

Function decoders are similar, except they lack the motor control functions.

Accessory decoders are used for turnouts, signals and other animated items.

Please see the decoder page for full details.

Edit FAQ Categories: Beginner, Decoder, Multifunction Decoder

Q: What can burn out a decoder?

- Overvoltage. For example, booster is set to incorrect scale.

- Current draw exceeds decoder ratings (wiring short or another overload condition). Poor wiring can cause this.

- Be careful when first testing a decoder installation. Put the vehicle with the newly installed decoder on a test track (programming track or section with a 100-ohm series resistor for current limiting) instead of the mainline for testing. This will limit the current, preventing damage if the decoder was miswired. If all functions work, and the vehicle can move (assuming motor output drive from decoder) at low speed steps, then it should be safe to place it on the mainline. As always, follow the manufacturer's instructions for testing in addition to the above.

- Overheating

- Imagine running a black loco in direct sunlight and hauling a heavy load at nearly the limit of the current output of the decoder. Now imagine the decoder only having current limits, and not thermal limits built in. Your imaginary decoder should running extremely hot. As you know, when things run too hot you'll let the magic smoke escape from the decoder. Avoid excessive loads for extended periods of time. If in doubt, check temperatures on newly installed decoders. If you find it running too hot, upgrade the decoder to handle larger currents and/or increase air flow around the decoder.

Q: Can you control things other than locomotive speed and direction?

Yes. The baseline packet in the standard only provides for basic locomotive control since that is all that is essential for interoperation. The extended packet format RP defines packets that can be used to control 32,000 different accessories such as lights, sound, turnouts, etc.

Edit FAQ

Categories: Beginner, Decoder

See more FAQs!

See Also

- Decoder installation - How to install mobile decoders

- Multifunction Decoder Troubleshooting

- Installing LEDs with DCC Decoders

- Throttles

- Configuration variable

- Decoder Reset

External Links

From the Australian NMRA site: