Rail Size

Summary: Model Railroads use various sizes of rail to represent prototypical trackwork. Rail sizes are expressed using the term Code.

Code 100 rail (commonly found in train sets or used to model heavy rail used on the mainlines, is 0.1 inches, or 100 thou (thousands) in height.

Many sizes of rail are used, to represent the way the prototype used rail for mainlines, yards, and sidings, depending on the loads and usage.

Common to HO are Code 100, Code 83 and Code 70. N scale modellers would use even lighter rail, otherwise in proportion to the model, Code 100 would look huge. Narrow gauge modellers would employ light rail, such as Code 70 or Code 55, to better recreate the look of a narrow-gauge railroad.

One issue that is very important is voltage drop. Proper feeder installation is important, as rail behaves just like wire: The smaller the cross-sectional area, the more impedance to a DCC signal. See the table below.

This is why the track must be wired using a power bus with feeders at regular intervals. A wire made of a nickel-silver alloy will have much more resistance than a similar wire made of pure copper. While nickel silver is in fact 60% copper, the alloy with nickel and zinc metals that give it the silvery appearance have a detrimental effect on conductivity. Brass rail is more conductive than NS rail, but less than that of pure copper.

Rail Impedance, Nickel Silver

Measuring a low resistance, such as a length of wire, is very difficult. Many DMMs have a 200Ω range as their lowest, meaning that attempts to make readings at very low values are not accurate. Their own errors will be more than the resistance of the rail sample. The leads used will introduce large errors as well. Even expensive laboratory grade instruments will have these issues. Measurement using 4 wire techniques is also possible, but at this low value accuracy will suffer.

Measuring rail, which is very low in resistance, requires much more current than the typical DMM will supply for the resistance range.

Since the DCC signal is periodic in nature, with fundamental and harmonic frequencies present, measuring the resistance with an Ohmmeter would not present the entire picture of how the rail interacts with the DCC signal.

Measurement Results

The following table gives the impedance of various codes of rail. The impedance was found with a 1A (at 60Hz) current flowing through the sample, using a comparator feeding a lock-in amplifier/detector, with the sensitivity set to 50μV. Adjusting the output of the phantom burden, the impedance of the rail is found when the measuring system is brought into balance (the detector reads 0V). This can be verified by measuring the voltage across the rail, where a DMM would indicate only a few millivolts. The phantom burden replaces any voltage drop across the sample of rail by creating an equal but opposite potential, bringing the system into equilibrium. The difference between the impedances required between no sample (null) and with a section of rail on one leg is the sample's impedance.

This is a very accurate but difficult to duplicate method without the proper instruments. The ability to null the lead impedance allows for a very accurate result. Attempting this measurement with general purpose test instruments would not yield accurate results.

This table uses the term Impedance to represent the rail's resistance, as the measurements were made using a 60 Hz AC source. This would also better represent the periodic nature of the DCC signal on the track.

| Code of Rail | Impedance per metre, mΩ | Equivalent Wire Gauge | Strands/Gauge |

|---|---|---|---|

| https://dccwiki.com/Rail_Size | |||

| 100 | 76 | 24 | 7/32 |

| 83 | 108 | 26 | 19/38 |

| 70 | 206 | 28 | 19/40 |

- The wire used for an equivalent is stranded. Since the measurements were made at 60Hz, impedance better reflects the results.

- Measurement accuracy is less than 50ppm. Actual resistance/impedance will vary by manufacturer due to alloy and profile. The samples were Micro Engineering flex track.

Why Different Sizes

The rail size or code indicates the height, and is used to represent the various types of rail used by the prototype. (H0 Scale)

| H0 Scale | Prototype Rail | ||

|---|---|---|---|

| Code | Pounds per yard | Height, inches | Application |

| 100 | 152 | 8.7 | PRR Heavy rail (155lb) used in the mountains |

| 83 | 126 | 7.1 | Main line applications |

| 75 | 114 | 6.5 | Main line, passing sidings |

| 70 | 100 | 6 | Sidings, industrial |

| 55 | 83 | 4.7 | Sidings, industrial, Narrow gauge railways |

| 40 | 60 | 3.5 | Narrow gauge and industrial railways |

In general, heavier tonnage, heavier rail. For N scale, divide the code number by 2, or for O, multiply by two to get an approximate size. For Example, the C83 equivalents for N are 45, and O, 148. So C40 and C150 are appropriate. The NMRA recommends C40 for all applications in N Scale. For more details see NMRA Data Sheet D9r Rail Size. Choosing the appropriate rail size will make your models look much more like a model.

In the 19th century, rail weights of 40 to 80 lbs per yard (approximately 20 to 40 kg/m) were typical. In the 20th century, weights increased to the 112 to 145 lbs seen today. For most modellers, Code 83 is the best compromise for main line trackage. Lighter rails can be represented by C70 and C55 rail for sidings, yards or lightly used branch lines. C100 can be used to represent the 155 lb. rail used by the Pennsylvania Railroad in their mountain districts.

Compatibility Issues

Compatibility between different brands of rail varies. It often is determined by the rolling mill and the profile they provided to the track manufacturer. There are only a few specialised rolling mills which make rail for model railroad applications, so there will be similar profiles between track brands.

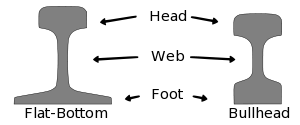

The profile generally involves three factors:

- Height, known as the code of the rail

- Width of the rail head

- Width of the foot (base)

Joining different brand of track isn't difficult. Providing the rail code matches, the height isn't an issue, while the thickness of the ties can be problematic. The problems usually involve the base or foot of the rail being wider or narrower than the other brand. Atlas, for example, designed their rail profiles to be compatible between their Code 100 and Code 83 lines. The Code 83 rail has a shorter web, but the base and rail head are similar. This makes the Atlas Code 83 track easy to mate with its Code 100 counterpart, with a very unprototypical head appearance.

Special rail joiners are also available to mate different rail codes.

See the Fast Tracks link below for more information.

See Also

External Links

- Can you make Assembly Fixtures for rail other than Micro Engineering? - Table with various rail sizes and their measurements by manufacturer from Fast Tracks