General Electric's ASTRAC

Summary: The ASTRAC or Automatic Simultaneous Train Control system was the first commercial command control system since Lionel's Electronic Control System. ASTRAC could also be described as a carrier control or analog command control system. ASTRAC was developed, manufactured and marketed by General Electric. It employed Silicon Controlled Rectifiers, General Electric's name for their new semiconductor device.

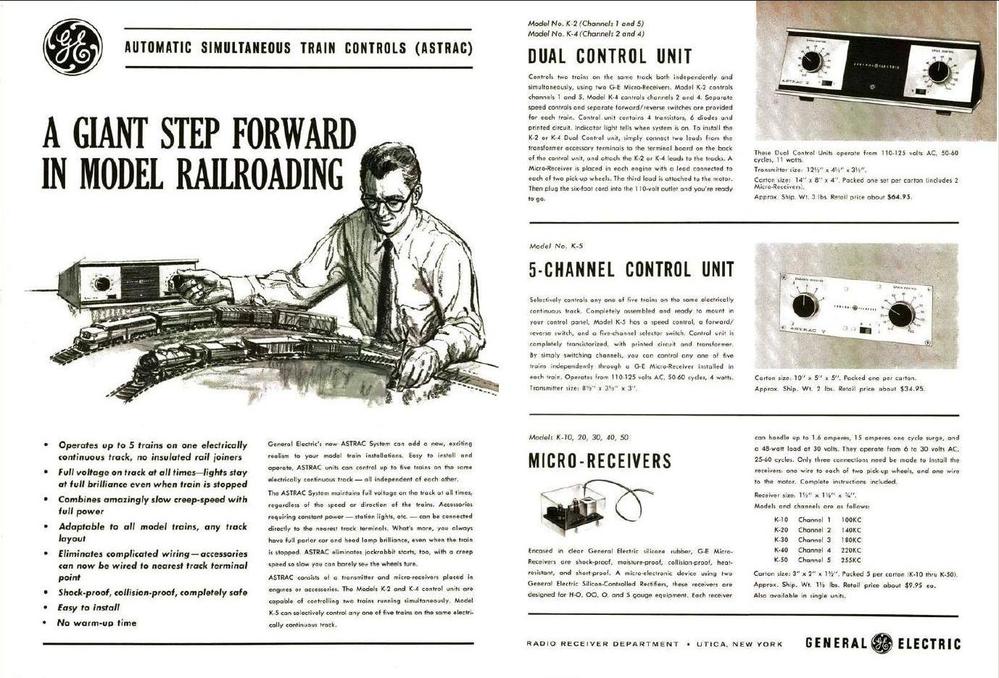

Automatic Simultaneous Train Control by General Electric

GE developed a thyristor device in 1958 which they called an SCR or Silicon Controlled Rectifier. One of its many applications was dimming lamps or controlling the speed of electric motors. Two SCRs be part of the receivers used by their ASTRAC system.

There were several carrier control systems announced in the years before ASTRAC was unveiled but all of them failed for a number of reasons, usually technical, financial, marketing, or a combination. ASTRAC seemed to have overcome those issues.

ASTRAC would disappear as quickly as it appeared. The next commercial command control system developed by a large corporation would be the Zero 1 by Hornby.

General Electric has a long history in railroading, from supplier of electrical equipment to locomotive builders for electric locomotives, to a supplier of electrical equipment to ALCO for their diesel electric locomotives. GE would also construct the Erie Built Fairbanks-Morse locomotives, the GE 44 Tonner, and later enter the locomotive business themselves in competition with former customer ALCO.

GE also constructed an unsuccessful steam turbine for Union Pacific in the 1930s, and would later build high horsepower GTEL locomotives (gas turbines) for UP.

GE today is the largest manufacturer of locomotives in North America.

History

GE enters model railroading field with ASTRAC control system which permits user to control up to 5 trains independently on one electrically continuous track. Heart of transistorized receiver mounted in train is pair of silicon-controlled rectifiers. Dual-control unit will retail for about $55, including 2 receivers. Five-channel control will sell for around $25, with optional micro-receivers at about $10 each.

- Television Digest, March 4, 1963

Introduced by the General Electric Company's Educational Products Engineering Section in the mid 1960s which developed and manufactured the system. ASTRAC used Frequency Modulated signals from 100 to 255kHz on the track to control micro-receivers in the locomotive. The recievers were tuned to a specific frequency, or channel. Not digital, but analog in nature. Five channels were supported, GE promised further improvements, such as more channels, in a future version. GE employed Silicon Controlled Rectifiers (SCRs) to control the motor.

General Electric announced ASTRAC in a multipage ad placed in the July 1963 issue of Model Railroader (Pages 14 and 15, Model Railroader, July 1963).

The ad claimed ASTRAC had a number of features, up to five trains in operation simultaneously, no complicated track wiring or gaps needed, no warmup time required, and installation was easy and safe. It was also shock-proof and collision proof. Accessories could be connected directly to the track, and constant lighting of parlour cars and headlights was possible with full voltage on the track at all times. GE also promised full power for full speed, as well as being able to creep along at speeds so slow you would have a hard time detecting movement. All this, and it would be easy to install and use. Reverse loops still needed to controlled with a toggle switch to prevent shorts.

With additional wiring and ASTRAC transmitters you could control more than 5 locomotives. It was also suggested that it would be possible to use direct current for analog locomotives and ASTRAC equipped locomotives at the same time. (Unknown if this was in reality possible, as a thyristor device cannot be switched off if connected to direct current, making control of the ASTRAC locomotive difficult at best.)

Power required for operation could be as high as 24VAC. The ASTRAC system needed an AC voltage, which it superimposed the FM signals onto. The AC voltage was then connected to the track.

If you had two K-5 transmitters, care was required to avoid having both units selecting the same channel. If that happened, the motor in the locomotive could overheat, and that happened quickly. The same caution applied to any multiple transmitter setup involving a K-5.

ASTRAC had a very short life span, GE dropped it soon afterwards. Why did General Electric market a command control system for model railroads? GE's ASTRAC was the result of a home automation system under development, which never made it to market. Since GE had no other mass market product using the technology, ASTRAC was destined to be a niche product. The adoption of ASTRAC by modellers was not fast enough for GE to consider it as a viable product. Being an expensive product at the time, its appeal would have been limited to those willing to make the investment. In comparison, the K2 or K4 transmitters would have retailed for more than $500 today, while decoders would be almost $80. Today that could buy you a really sophisticated Digital Command Control starter set for the same money. Decoders, you could buy several basic DCC decoders for the cost of one ASTRAC micro receiver.

Components

Transmitters

The ASTRAC system comprised of several components:

- Dual Control unit

- Model K-2, controlled channels 1 and 5

- Model K-4, controlled channels 2 and 4

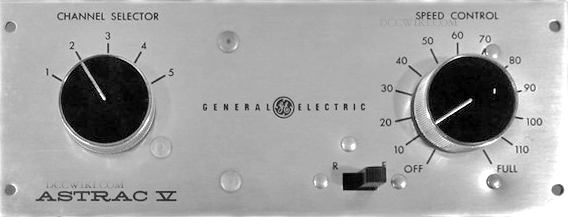

- Model K-5, which could select any of the five channels. It was designed for panel mounting unlike the K-2 and K-4.

The K-2 and K-4 were mounted in cabinets, with a knob for speed control and a slide switch for selecting direction. The K-5 had two knobs, one on the left for selecting the channel, the right hand knob for speed control, plus a switch to select direction. The ad said installation was simple, just two wires to the track, plug the transmitter into wall, and you were ready to go. The K–5 also had a connector for future expansion.

Track power was supplied by a 6 – 30VAC, 25 to 60Hz transformer (16 – 18VAC recommended), and the transmitter was wired in parallel to it. A transformer was not included with the ASTRAC system.

If more than one transmitter was installed, they were wired in series. All five channels could be used with a II, IV and V wired in series. Each unit had its own power supply, to supply power to operate the electronics. Track power supplied the synchronization for correct timing of the transmitter.

GE's suggested retail price was $64.95 for the K-2/K-4, and $34.95 for the K-5.

Note: The ASTRAC transmitters were identified with a Roman numeral: a K-2 has II on the panel, and a K-5 is identified with a V. There never were any revisions past the original production. A device identified as an ASTRAC II is a K-2.

ASTRAC K-7

GE planned but never released the K-7 Transmitter. It was similar to the K-5 except for the channels. The K-7 expanded the ASTRAC system to 10 channels, by adding additional channels in the 50 to 90kHz range.

Micro Receivers

- Main article: ASTRAC/Receiver Technical Details

GE also sold the "micro-receivers" which were installed in the motive power. They could handle 1.6A continuous, and up to a 15A surge. They were encapsulated in clear GE Silicone. This made them shock proof, moisture proof, heat resistant and short proof. GE claimed they could be installed in HO, OO, O and S scale equipment. The decoders measured 1 1/2 x 1 1/8 x 3/4", and employed to SCRs. Since they were potted in silicone, adjustments were difficult to do. At the same time, the IF can was protected from tampering.

GE claimed their ASTRAC system eliminated jackrabbit starts, providing realistic starting and crawling speeds. The power available at low speed permitted pulling two stalled locomotives on a 5-percent grade at a slow crawl.

Channels

Receivers were as follows:

- K-10, 100kHz

- K-20, 140kHz

- K-30, 180kHz

- K-40, 220kHz

- K-50, 255kHz

The retail price was $9.95.

The receiver had three wires, the black and white went to the rails and the third red wire was connected to the motor. The channel was indicated by the first digit in the model number. Two on the same channel could be used for a double header.

The included instructions indicated you could alter the form factor of the micro receiver if needed, and included a carbon resistor for wiring in series with the headlights to protect the bulbs. It also stated that a rectifier and resistor could also be used with track powered accessories.

Additional Channels

To complement the planned K-7 transmitter additional micro-receivers were planned to allow 10 channels in total.

Upgraded Receivers

GE also planned to update their receivers with a smaller form factor, as well as a trimming pot to allow adjustment of the slow speed operation.

Installation of Receivers

Wiring and installation was very similar to the later Hornby Zero 1 system. The thyristors in the receiver allowed the DC motor to be operated safely on the AC track power. The receivers were encapsulated in silicon rubber, which could be trimmed to fit an oddly shaped body.

Much like other command control systems, a locomotive without a receiver could not be operated on a layout employing ASTRAC. It was possible to burn out the headlights (excessive voltage) while the motor would emit a loud buzz. Until it overheated.

There were concerns that the 60Hz AC on the track would weaken the motor magnets. This was found to be a non-issue, as the voltages and currents required are much higher than those used with ASTRAC.

System Configuration

A basic system could be constructed using a K-2, K-4 or K-5 transmitter, and the appropriate receivers. This would allow for 1 locomotive with the K-5, or two using a K-2 or K-3, with the appropriate receivers. Power was supplied from a 16 to 20VAC transformer.

A more advanced system could be constructed with a K-2/K-4 with a K-5 attached in series. This would control of up to three locomotives at once. Connecting a K-2, K-4 and a K-5 transmitter together allowed control of 5 locomotives at once.

Advantages and Disadvantages

- "The General Electric Company's ASTRAC is a marked commercial advance in the field of model railroad controls. It has limitations which, if observed by the user and not violated, are more than offset by the advantages which may be obtained."

-Letter in the NMRA Bulletin, Feb. 1964.

Advantages

ASTRAC had a number of advantages.

- It shared with DCC the simplification of wiring and the elimination of blocks

- Contemporary reports stated that up to 75% of the wiring was eliminated with ASTRAC

- One of its biggest advantages was true cab control of an individual locomotive without needing blocks, which enhanced realism

- Constant power on the track was seen as a benefit for constant lighting applications

Disadvantages

- The nature of the voltage applied to the motor was the source of a few issues:

- Overheating, noise, and reduced top speeds

- The motors of the time would have had problems with the 60Hz pulses supplied by the receiver

- The low frequency would cause motor noise

- As heat built up in the shell, the decoder could drift off frequency, making operations interesting

- The limited current capacity of the receiver excluded many O Scale locomotives

- Pulse power method employed required twice as much current

- The size of the receiver limited installation options. Too large for some applications, necessitating installation in a dummy unit or a permanently coupled boxcar

- Many smaller locomotives such as switchers lacked the room for the micro receiver, distracting from prototype operations

- It was possible to cut the receiver in half to aid in fitting it, but that could be problematic due to the tuned circuits present

- Slow speed operations were an issue

- No independent control of the headlight

- Cost: At approximately $35 per channel, the modeller would need to balance operational realism against more locomotives

- The limitation of five channels wasn't seen as an issue on a home, or some club layouts, but could require planning as to motive power used in an operating session or require additional ASTRAC transmitters in separate areas of the layout

- A locomotive which was not fitted with an ASTRAC receiver could not be placed on the track. Doing so would burn out the motor, or demagnetize it. Mixed DC-ASTRAC operations could be possible, but caution was required to avoid damage to a receiver-less locomotive

- Detection systems using relays in series with the track blocked the ASTRAC carrier. A change in detection methods would be required

Despite ASTRAC being developed and marketed by a large, well-financed corporation, it disappeared very quickly when management decided to cut their losses by discontinuing the ASTRAC product line.

Cost of ASTRAC Components

The cost of the components could also be seen as a liability to the ASTRAC system. While $9.95 (in 1964) may look like a good deal, when converted into what it is equivalent to in 2021, it is another story. Where one of the main criticisms of Digital Command Control is the cost, an ASTRAC receiver would have had a suggested retail price of almost $90 in today's money. (Average annual income in the US at the time (1964) was $6000 and a US gallon of gasoline was 30 cents (or 8 cents a litre)). The average new car cost $3500 at the time of ASTRAC's introduction.

Compare the equivalent price of $90 to what a very basic Digital Command Control Decoder sells for today.

The price of the two channel K2 or K4 transmitter would be equivalent to $515 today, while the single channel K5 would cost you $277.

Purchasing a complete K2, K4 and K5 for a five channel setup for your layout would cost $165, plus 5 receivers at $49.75. Which is $1500 in 2021, plus an additional $440 for the receivers.

Compared to DCC, it is a lot of money for what would be seen today as a very limited feature set. To put together a complete system for five operators, using a pair of K2 and K4 transmitters, with a K5 (total $295), and equipping five locomotives with receivers ($50) would set a layout owner back almost $2000 in 2021 dollars. The operators would also have to exercise great care to ensure that two transmitters were not selected for the same channel, otherwise damage to the locomotive and system was possible.

The steep cost alone would have deterred many modellers from adopting ASTRAC, a liability which would be evident in the command control market until the arrival of the low-cost digital technology which makes Digital Command Control possible.

Coverage in the Model Railroad Press

An article in the December 1963 issue of Model Railroader was entitled Is ASTRAC on the Right Track? It was also mentioned in the magazine that General Electric was considering a 7A receiver for O scale.

By the summer of 1964 GE had suspended further development, by 1965 they were clearing out their ASTRAC inventory. In August 1965 a note in Model Railroader Magazine made it official: GE was dumping their ASTRAC system, as it had not lived up to their expectations. GE felt that the market was not there, thus they could not continue to commit resources to an expensive product line with limited appeal.

ASTRAC also had a chapter in The Complete Book of Model Railroading, published in 1964.

Railway Modeller April 1964

UK publication Railway Modeller had a short article on ASTRAC:

Railway Modeller April 1964

ASTRAC

Is this the answer to control?

by C. J. Freezer

This article has been prepared from material kindly supplied by the Model Railroader magazine of Milwaukee, USA, to which we are particularly indebted for the full-size photographs of the Astrac micro-receiver on the right.

FOR some considerable time, the idea of carrier control for model railways has been kicked about by electronic experts. The idea is simple: you apply constant power supply to the track, superimpose a tuned high-frequency control signal over your constant power supply to operate a receiver in the locomotive, which sets speed and direction. Each locomotive has its receiver tuned to a different wavelength so that you can control any locomotive you like without any need to use section switches. The idea is almost the only simple thing about it.

However, the General Electric Corporation of the U.S.A. has managed to iron out enough of the difficulties to produce a workable unit which can be applied to a small scale railway. The system is called ASTRAC, and is obtainable commercially in the USA. In the December 1963 Model Railroader Linn Westcott, the editor, published a long article, and for those particularly interested I can do no better than to refer them to the original. At the moment we are hoping to get some samples for evaluation, but in order that readers can know what is the latest development in control I am, through the kind permission of Linn Westcott, able to present the bare bones of the system.

First and foremost, Astrac does not eliminate the need for two-rail feeds to be correctly located, nor does it provide an answer to the perennial headache of the reversing loop. All it eliminates is the manual switchboard.

It is in its present form limited to only five channels. These are analogous to the channels on a television tuner, except that with Astray it is the frequency of the transmitter that is altered to correspond to that of the receiver in a specific locomotive. This does not, of course, limit you to only five locomotives, for the duplicates can be safely housed on dead sidings, or, in the case of a really large layout, two separate Astrac areas could be maintained. But it does increase complications, particularly when rostering your stud for timetable working, since obviously you can't run both channel 1 locos at once!

The big surprise is that Astrac employs AC for the track. It controls the locomotives by switching the motor on and off for a fraction of each pulse of the appropriate half wave of the AC supply. The direction is governed by whether the positive or negative pulse is employed, the speed by the duration of the pulse. This extremely rapid switching seems at first sight fantastic, but it is well within the capacity of transistor switchgear.

What do I think of Astrac? Well, without having inspected the gear and tried it for myself I am reserving judgment. However, some obvious conclusions can be drawn.

Astrac has three things in its favour. It simplifies wiring, for although you have still to observe correct feed points you simply loop all feeds and all returns together. This goes one better than common return — it's common feed as well! Second, it simplifies control, even on quite complex layouts. Instead of a battery of switches you have an extra selector on each controller. Set the channel selector to the required locomotive's channel and drive off. No worries about setting routes, or even conflicting routes! Finally, train lights can be worked off the AC supply, and don't go off when the loco is stopped.

There are also snags. For a start, each locomotive has to be fitted with a receiver, so only specially equipped locomotives can be employed. It is possible to combine both Astrac and conventional DC systems, but the complications are such that I doubt if anyone would bother.

Second, since locos are working on pulse power you get extra noise, and in some cases heating problems. This may necessitate a change of motor.

Third, you are limited in practice to five locos out on the track at once. This, I think, is a theoretical rather than a practical objection, since the fourth snag lies in the cost. The receivers cost about 10 dollars, the controllers about 50 dollars. Their price in the U.K would depend on import duties and purchase tax. However, the fourth snag could be overcome if production goes up.

There might appear to be a fifth snag — Size. The photograph shows the receiver, which is neatly sealed in transparent synthetic rubber, which can, within limits, be pared down. It will fit into most tenders, though you might have to pile the coal on a trifle, and can be squeezed into most large tanks. In one respect we are luckier than the Americans, for although we might not be able to fit it into a shunter it can be fitted into a permanently coupled shunter's truck. But small as the receiver might be, those readers well up in the latest electronic developments will know that, except for the coil, each component could be replaced by a smaller fitting currently in production. In fact, I learn from Linn Westcott that a smaller receiver is being developed.

My conclusions? Well, although I've listed three advantages against five snags, the difficulties can be overcome to a very considerable degree, and two of the advantages are overwhelmingly big ones. The potentialities on the proprietary market are tremendous; indeed, I think Astrac is just what the train set needs to regain public interest With the backing of a major manufacturer the apparent difficulties of price and size could be considerably minimized, for this is the present trend throughout the electronic industry.

THE PRINCIPLE OF ASTRAC

Full speed forward. The unit is switched "on" for the entire duration of the forward-going half of the AC wave.

Mid speed forward. The unit is switched "on" for part of the duration of the forward-going pulse. Note that the voltage is constant, the duration of the pulse is reduced.

Slow “on" speed forward. The unit is switched for only a fraction of the pulse.

Reverse running is achieved by switching on in the alternate, reverse-going half of the AC wave.

Notable Users

W. Allen McClelland was an early adopter of the system, which was documented in the April 1966 (Model Railroader) issue, How I Adapted my Astrac for Walkround Control. The article began with a disclaimer indicating that GE had dropped support and no longer supplied the ASTRAC system during the time the article was being written and prepared for publication.

The V&O would later convert to CTC-16 using the commercially produced DIGIPAC316 system.

Systems Related to ASTRAC

ASTRAC would be resurrected by Alphatronics in the early 1970s with a compatible system, which offered the ten channels GE originally promised. The Alphatronics system would be available until 1980.

Read More about Command Control Systems

- See the article on DCC History for more about the history and development of command control, carrier control, and Digital Command Control.

Model Railroad Academy

The Model Railroad Academy has a short video preview "Digital Command Control with Jim Providenza" which mentions ASTRAC.

Notes

Dollar values for 2021 established using the inflation calculator.

Goldfinger, the 1964 James Bond film featured a layout controlled by ASTRAC owned by the villain, Goldfinger.

References

GE Advertisment:

- Pages 14 and 15, Model Railroader, July 1963.

References in model railroad related magazines:

| Title | Publication | Year | Month | Page |

|---|---|---|---|---|

| ASTRAC | Model Railroader | 78 | 04 | 138 |

| ASTRAC AND WALKAROUND CONTROL | 66 | 04 | 46 | |

| ASTRAC SYSTEM ON THE RIGHT TRACK? | 63 | 12 | 33 | |

| ASTRAC ONE MORE TIME (MAYBE) COMMENTS | Railroad Model Craftsman | 73 | 16 | 48 |

| GE ASTRAC CONTROL SYSTEM DISCUSSION | 71 | 04 | 64 |

Source: http://magazine.trainlife.com/wp-content/uploads/2017/08/mrr_199009.pdf p14

- Archive issues of MR are available on-line through Kalmbach Media (subscription required). Unfortunately there is no archive of RMC available.

- The Complete Book of Model Railroading by David Sutton (1964)

- ISBN0890094454

- ISBN13: 9780890094457

- ISBN0890094454

http://retailers.kalmbach.com/sitefiles/catalogsamples/12417spread.pdf